- Home

- Thermal Management

- Heaters

- Aluminium Foil Heaters - IP68

- Cartridge Heaters

- Cast Heaters

- Ceramic Knuckle Heaters

- Coil Heaters, Coiled Heater Bands and Nozzle Heaters

- Custom Heaters

- Drum Heaters

- Finned Air Heaters

- Flanged Heaters

- Flat Tubular Heaters

- Flexible Tubular Heaters

- Heating Cables, Crankcase Heater

- Immersion Heaters

- Mica Insulated Heaters, Mica Band Heaters, Mica Plate Heaters

- PTC Self-regulating Heating Elements

- Silicone Mat Heaters, Wire Wound, Etched Foil

- Tape Heaters

- Thick Film Heating Elements

- Tubular Heaters

- Temperature sensors

- Temperature controllers

- Products

- Contact

Cartridge Heaters

One of Clarian's specialites! Cylindrically ground cartridge heaters for greater accuracy and longer life. Our exceptional service provides you with the EXACT cartridge heater you need.

Cartridge Heaters - We have the solution

- High performance

- Maximum accuracy

- High surface loading (smallest volume; maximum power)

- Ground sheath

- Longer lasting

- Huge range of choices to suit you

Use our easy reference tables to find the exact cartridge you need.

- clarian.jpg

Clarian UK Ltd is a long establshed British company.

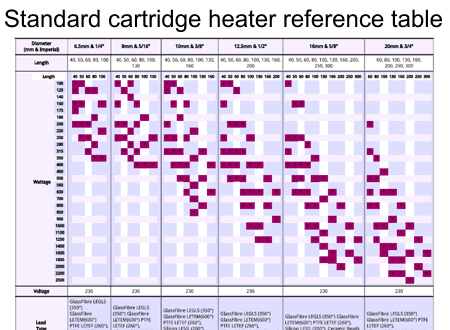

- cartridge-heaters-reference-table.png

Standard Cartridge Heaters reference table

- heaters.jpg

Exclusive UK agent for Turk and Hillinger and Heatfor.

- cartridge-heaters.jpg

Cartridge heaters are one of Clarians specialist areas.

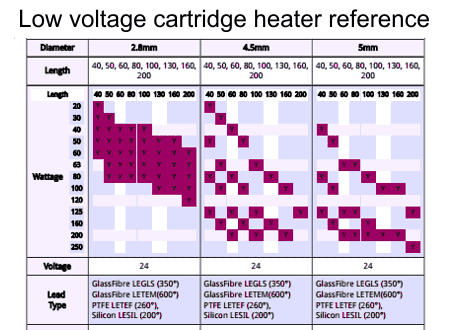

- low-voltage-cartridge-heaters-reference-table.png

Loe Voltage Cartridge Heaters reference table

- turk-hillinger-uk-agent.jpg

Exclusive UK agent for Turk and Hillinger.

Bespoke Design to Suit Your Exact Requirements

- Metric or imperial sizes

- Choice of diameters from 2.8mm

- Choice of lengths up to 6 metres

- Choice of cables

- Choice of cable exits

- Moisture protection available

- Wattage distributed to specific areas of the cartridge as required

- Low, high or dual voltage

- Integrated temperature sensor

- Self regulating ptc elements

- Special mechanical fittings and connectors available

Hot tips

When fitting cartridge heaters. Keep the fit between the cartridge heater and hole as tight as possible ideally applying an H7 fit.

On this page:

High performance cartridge heater

Metal-sheathed cartridge heater with ground sheath. The special construction allows an extremely high surface loading, i.e. maximum power in the smallest possible space. Cartridge heaters are normally inserted into a metal block due to there high surface loading. Our cartridge heaters can be made with distributed wattage allowing greater heater output at the ends as opposed to the middle. They can also be made with low(24v) and high voltages as well as dual voltages and incorporate temperature sensors. We can also supply cartridge heaters with self regulating ptc elements if required and in very small diameters down to 2.8mm. We can also supply very long cartridge heaters up to 6 metres in length and heaters with special mechanical fittings and connectors.

Applications include; Plastics, apparatus construction, woodworking, paper machinery, medical technology, foundries, high vacuum technology, laboratories , packaging.

Cartridge heater connection and lead options

Connection types

Normanschluss NA

leads connected outside

ISAN

insulated connections

DIRFLEX

leads directly coming out

HLP

with pins only

Connection leads

LEGLS

glassfibre insulated leads

250°C/350°C*

LETEM

temp. resistant glassfibre leads

400°C/600°C*

LETEF

PTFE-insul. leads up to 260°C

LEPE

ceramic beads up to 650°C

LESIL

silicone insul. leads up to 200°C

AE

coreend shells

SERD

earth lead

KASIL

with silicone insulated cable water resistant

Protective hoses

SSL

protective hose

WSL

corrugated hose (stainless steel)

DRGSL

wire mesh hose

GLSSL

glass fibre insulated protection

Additional options

EN

threaded nipple

WAN

angular connection

WAN RUND

angular round connection

WAN 90

angular round connection

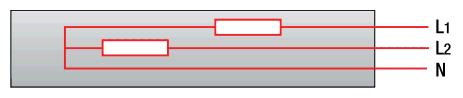

HEATED ZONES

Cartridge Heaters (PDF datasheet). Specials, product enquiry and further information (Contact us form).

- possible for all HLP and HLP/T type heaters

- not available ex-stock

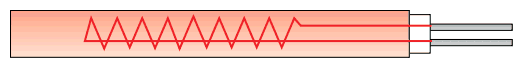

Standard heat distribution

![]()

Unheated zone on connection side and/or far end

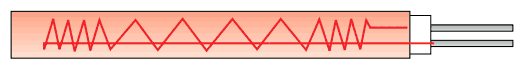

Reinforced power distribution on one or both ends

Unheated in the middle of the heater

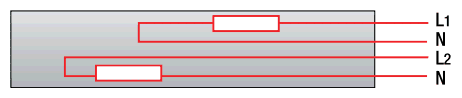

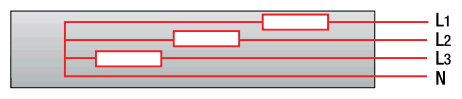

DUAL VOLTAGE TYPES

Cartridge Heaters (PDF datasheet). Specials, product enquiry and further information (Contact us form).

- allows separate heating of zones

- not available ex-stock

Version 1 (2 switchable zones / 3 connection leads)

Version 2 (2 switchable zones / 4 connection leads)

Version 3 (3 switchable zones / 4 connections leads)

HLP T WITH THERMOCOUPLE

More about - HLP T with Thermocouple Specials, product enquiry and further information (Contact us form)

General information

All HLP type heaters can be supplied with an integrated thermocouple. Heaters mentioned in the table are available ex-stock. High performance cartridge heaters are especially suitable for internally heated nozzles and heated torpedos where, due to space considerations, a separate thermocouple cannot be installed. The thermocouple is fixed in position, compacted and potential free insulated from the sheath or alternatively connected with the heater sheath.

Execution

Compensating leads can be connected to specified requirements. The thermocouple is galvanically separated from the cartridge sheath unless otherwise specified at the time of ordering. HLPT can also be supplied with an electrical connection between the thermocouple and the cartridge sheath, if so desired.

HLP T WITH PT 1000/PT 100/NTC

More about - HLP T with PT 1000/PT 100/NTC Specials, product enquiry and further information (Contact us form)

General information

All HLP type heaters can be manufactured with an integrated temperature sensor i.a.w. DIN EN 60751 (PT 100) or with an integrated NTC-sensor (negative temperature coefficient) for precise temperature measurement. Typical fields of application therefore are within the car industry, electrodomestical appliances, air conditioning devices, for general machinery and medical technique appliances.

Advantages

- High precision over a wide temperature range

- High reliability

- Materials of the connection leads can be freely chosen other than for thermocouple wires

TYPE PMV (LIGHTLY COMPACTED)

More about - Type PMV (Lightly Compacted) Specials, product enquiry and further information (Contact us form)

Characteristics

The lightly compacted cartridge heaters of this series distinguish themselves by a higher immunity against mechanical shock, and by a substantially longer useful life as compared with noncompacted metal sheathed cartridge heaters of the same surface load. They are suitable for heating liquids, gaseous and solid media and resist arduous service conditions in industrial applications.

Technical Data

similar to the high performance cartridge heaters type HLP, however:

Maximum surface load: approx. 6,5 W/cm2 (on the sheath)

Tolerances: Diameter: +0,2 mm of the groundless covering.

Upon request these can be ground to finer tolerances -0,02 to 0,08 mm

Length: 1.5% at least, however 2 mm

Capacity: 10%

CONICAL SHAPE, TYPE HLPK

More about - Conical Shape, Type HLPK Specials, product enquiry and further information (Contact us form)

Characteristics

The high performance cartidge heater type HLPK has a conically tapered sheath with a taper ratio 1:50 i.a.w. DIN 1 for standard taper pins. The conical shape of the cartridge heater guarantees an exact force fit in the workpiece. In the case of accurately reamed bores, there is an excellent fit, as the cartridge heater in this case takes a slightly deeper installation depth. An excellent heat distribution results from the exact fit and, thus, the danger of overheating the cartridge heater is kept low. In order to get an even temperature profile, the cartridge heaters type HLPK are equipped with reinforced performance zones on both sides.

Applications

Heating of founding tanks, die- and mold making, cigarette-machines, machines for shoe production.

HLP FOR LOW VOLTAGES

More about - HLP for Low Voltages Specials, product enquiry and further information (Contact us form)

General Information

These highly compacted heating elements have been developed primarily for the heating of small parts. The sheath is made of chrome-nickel steel, material no. 1.4541 and serves as a return conductor. Therefore the high performance cartridge heaters type HLP 2.8; HLP 4.5 and HLP 5.0 may only be used for operation at low voltages up to 42 V max.

Technical Data

The sheath of the cartridge heaters for low voltages is not ground (diameter 2.8 mm -0.1 mm; 4.5 mm ?0.1 mm and 5.0 mm ?0.1 mm) . The bottom end is welded gas and liquid tight. The maximum sheath temperature for the ? 2.8 mm and ? 4.5 mm heaters is approx. 500?C and 750?C for the ? 5.0 mm cartridges. The connection cable for the low voltage cartridge heater with diameter 2.8 and 4.5 mm consists of a 100 mm long twisted wire which is insulated by a teflon hose. The teflon insulation can withstand temperatures up to 300?C at short time use and 250?C for permanent use. The connection end of the ? 5.0 mm heating elements consists of a ? 2 mm connection bolt with a length of 20 mm.

SELFREGULATING CARTRIDGE HEATER TYPE HLPR

More about - Selfregulating Cartridge Heater Type HLPR Specials, product enquiry and further information (Contact us form)

Function

The self regulating cartridge heater type HLPR is a compacted heating element with PTC-effect (positive temperature coefficient: performance decreases the more that the temperature increases). When the temperature on the sheath of the heater increases, the performance is automatically reduced due to the increasing resistance within the PTC elements. The cartridge heater regulates itself, any additional control equipment is not required.

Construction and advantages

Compared to conventional high performance cartridge heaters with a nearly constant ohmic value, HLPR heaters consist of an integrated semiconductor element. The resistance of the heater varies and increases automatically with the rising temperature and the power consumption and the current is reduced to a minimum when the heater reaches its maximum temperature. This makes the heater very economical and extends its lifetime.

HLPR FOR RADIATORS

More about - HLPR for Radiators Specials, product enquiry and further information (Contact us form)

Function

This self regulating HLPR type heater with a long shaft has been developped especially for the use within radiators.

Advantages

- no switches which are subject to mechanical wear

- the allowable maximum temperatures will not be exceeded at any time due to the physical properties of the PTC-element

- the heaters are not sensitive to variations in voltage they can be run from 200 V through 265 V

- dielectric strength 4000 V

Connection types

- Cable with connector

- Cable without connector

- Normal connection leads

HEATING OF EXPANSION SCREWS

More about - Heating of Expansion Screws Specials, product enquiry and further information (Contact us form)

Special type HLP heaters for the heating of expansion screws or other special applications

Description

Expansion screws are always used where the tightening of the screw has to assure a long lasting and solid connection. This is mostly used for large electrical machines like turbines and generators or for large diesel engines e.g. for ships. The tightening of the screw serves to assure that the housing halves of the machines are safely fitted and that they can withstand the mechanical load during operation such as vibration or pressure. The screws can also be used for the fixation of the machines to a socket. The use of expansion screws is based on the elongation of the steel shaft within certain limits which is proportional to the applied heat. Expansion screws return back to the same length when cooling down to ambient temperature.

Important for ordering

Heated length, unheated length, voltage, performance, connection type. It is useful to provide the heaters with an unheated length of about 150 mm to 200 mm at the connection side to prevent the connection from being thermally damaged during the heating process.

INSTALLATION GUIDANCE

13 points to be observed when using highly compacted heating elements

- For cartridge heaters with surface loads up to 20 W/cm2 the receiving hole must be drilled according to ISA H7 with peak to valley height as small as possible.

- For cartridge heaters with surface loads exceeding 20 W/cm2 a press fit is necessary which can be obtained by individual attention beeing paid to each cartridge heater.

- The drilled receiving bores of cartridge heaters must be cylindrical. Crossing bores and shrinkages cause a localisation of heat and shorten the useful life of the heating elements.

- To facilitate the insertion and the removal of the heating elements the receiving bores should be drilled in a continuous motion (to avoid a stepped bore).

- The maximum working temperature of the cartridge heaters stated in the leaflet does not apply to the connection leads. These must be selected according to the operating conditions.

- The lubricant VARYBOND REGULAR GRADE beeing resistant to temperature facilitates the in sertion and removal of the heating elements in bores with small tolerances.

- When using several cartridge heaters the distance between two con - secutive cartridges should be at least equal to the cartridge diameter.

- The end of the cartridge heater with the connection leads should be protected against liquid and pasty media (lubricants, oil, synthetic materials, etc.) as well as their vapours because otherwise leakage currents and, possibly flashover could occur at the outlet connection terminals.

- The connection leads should be protected against mechanical vibrations close to the outlet of the cartridge heater. If they are heated with the cartridge, the resulting vapour must have the ability to escape.

- If possible, control of the operating temperature should be achieved by means of continuous regulators, controllers with pulse width modulation or electronic power control devices. A control system with long timelag often causes thermal overload of the heating elements. For this reason also the temperature sensor must be fitted in close proximity to the cartridge heater (about 10 mm apart).

- If heating elements are to be stored for long periods they should be housed in absolutely dry rooms or enclosed in plastic bags which are hermetically sealed. If cartridge heaters are moist, they can be dried by heating at 180?C for 8 hours.

- If the heaters are not supplied with a separate earth lead the installation has to provide a safe ground connection.

- Caution: In some cases silicone can run out of cartridge heaters. Please ask us if you wish cartridge heaters free of silicone.

Product enquiry and further information

We would be delighted to offer free application advice, technical information on products, free quotations and delivery information.